Environment

Resource Circulation in Product Lifecycle

Product Lifecycle and Initiatives at Each Stage

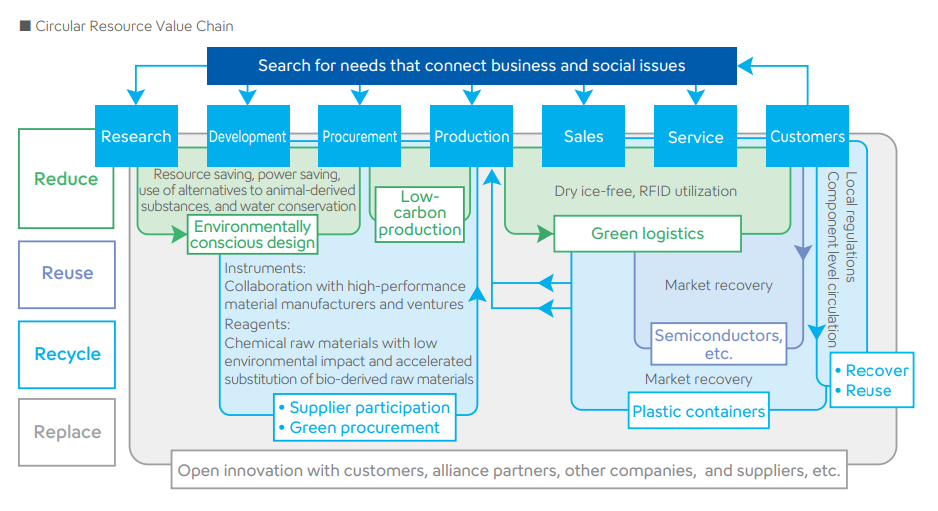

Sysmex undertakes a variety of initiatives at all stages of its business activities to reduce environmental impact throughout product lifecycles, with a focus on dependencies and impacts. From fiscal 2023, in addition to our activities to date, we are promoting activities to realize a circular resource value chain based on our Eco-social Strategy, which has been outlined as one of our core strategies in the long-term corporate strategy.

Environmentally Conscious Research and Development

Energy Saving and Miniaturization of Products

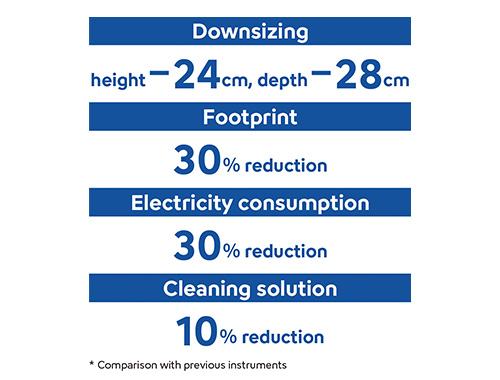

Compared to previous products with similar functions, the sample transportation system modules for the hematology analyzer released in 2021 are smaller in width by 15% and use 40% less electricity. Our fully automated urine particle analyzer launched in 2022 is 30% smaller and uses 10% less of the required cleaning solution per measurement than conventional units. It also consumes 30% less electricity, realizing an eco-friendly design.

Internal Program “Environmental academy” to Promote Green Innovation

Starting in fiscal 2024, Sysmex launched an internal program “Environmental academy.” In this program, leaders mainly from the R&D divisions engage in discussions to realize environmentally conscious product design. From fiscal 2025, the program will be expanded to include major divisions in the value chain, positioning environmental impact reduction as a key factor in new product development and model changes, thereby promoting green innovation through the practice of the Eco-social Strategy.

Development of Non-Animal-Derived Products (Biodiversity Considerations)

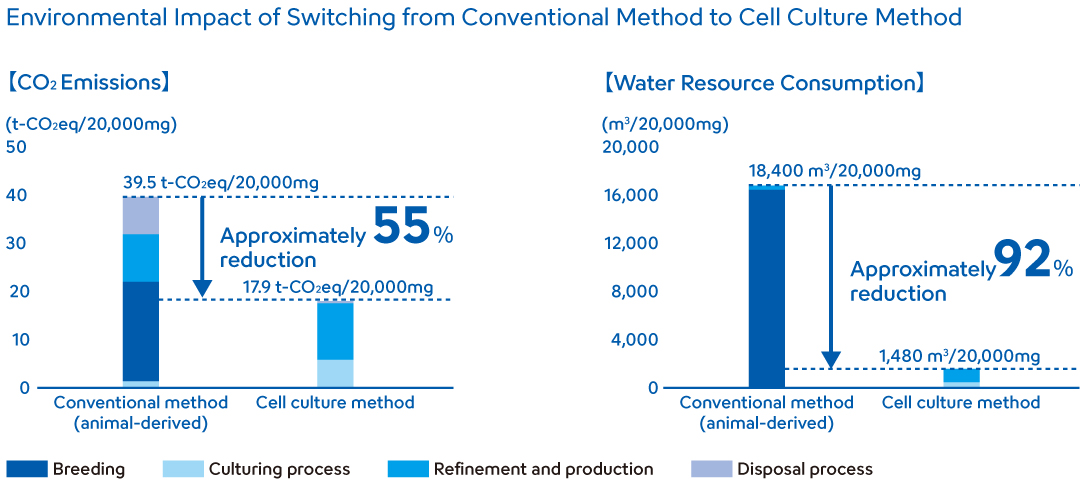

To reduce the use of natural resources, Sysmex Corporation has established a method of producing animal-derived proteins that can be deployed for diagnostic agents. The technique uses silkworms or cultured cells. In the past, producing these substances consumed a great deal of energy. However, as silkworms can be raised indoors and only need to be fed artificial food in containers, we can ensure a stable supply and quality of the substances. We are also able to save energy and reduce carbon dioxide emissions, water consumption, and waste.

We use genetically modified proteins produced from silkworms as ingredients for a reagent for hemostasis tests launched in fiscal 2017. This reagent, which uses genetically modified proteins as ingredients, is the first in Japan to obtain manufacturing and marketing approval. Furthermore, for other reagents, we are considering the development and application of new raw materials utilizing gene-recombinant technology, and are working to expand our product lineup with consideration for biodiversity.

To quantify the environmental impact of the change in the production method, we conducted a lifecycle assessment jointly with Professor Norihiro Itsubo of Tokyo City University (currently of Waseda University). The assessment confirmed that the new process reduces carbon dioxide emissions by more than 50 percent compared with conventional methods.

Environmentally Conscious Procurement

Promoting Green Procurement

Sysmex has established Green Procurement Standards, which set out the Company’s fundamental stance on environmental considerations in procurement activities. We promote the procurement of raw materials and parts that have a low environmental impact. We are expanding our business with suppliers who act to protect the environment. We also conduct annual CSR surveys of each supplier to confirm that they have environmental management policies in place, as well as targets and plans for CO2 reduction and energy conservation.

At the procurement policy briefing in 2023, we introduced our Eco-social Strategy. We also requested collaboration from suppliers in reducing CO2 emissions and implementing various environmentally friendly measures, and recognized suppliers that achieved progress in environmental initiatives.

In working to reduce Scope 3 emissions, we have set engagement targets to encourage suppliers to obtain SBTi certification or establish equivalent targets, and Sysmex has also received certification from SBTi.

Toward achieving these engagement targets, in fiscal 2024, we held a study session for suppliers to share the importance of obtaining SBTi certification, setting reduction targets, as well as best practices in reduction initiatives. Approximately 130 suppliers participated in this session.

Chemical Substance Management of Products

Sysmex complies with regulations governing chemical substances in each country and region, including RoHS Directives that restrict the use of certain hazardous substances in electrical and electronic products, and the Stockholm Convention (POPs Convention), which internationally regulates persistent organic pollutants.

To comply with these regulations, we have set standards to manage the chemical substances in our products. This includes managing environmentally hazardous substances in the components, devices, and reagent solutions that make up the products we produce and sell.

- Containing Prohibited Substances (Products)(255KB)

- Containing Substances Scheduled to be Prohibited (Products)(54KB)

- Containing Controlled Substances (Products)(217KB)

- Containing Prohibited Substances (Chemicals)(228KB)

- Containing Substances Scheduled to be Prohibited (Chemicals)(175KB)

- Containing Controlled Substances (Chemicals)(357KB)

Environmental Consideration in Product Transportation, Sales, and Services

CO₂ Reduction Through Modal Shifts and Manufacturing Transfer

We are also engaged in joint transportation with companies from other industries and in considering efficient global transportation routes. Furthermore, by transferring production facilities for reagent products, we are shortening transportation distances between facilities and thereby reducing CO2 emissions associated with logistics.

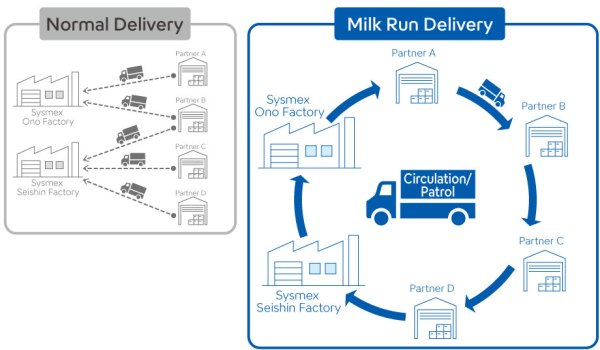

For the transportation of reagent raw materials and instrument components, we have introduced the “milk run method” (a system in which a single vehicle makes scheduled rounds to multiple business partners for collection and delivery), thereby reducing CO2 emissions through improved vehicle operation efficiency.

Progress is also being made in transferring production facilities. At Sysmex Wuxi, in addition to reagent products, we have achieved in-house production of reagent containers with complex structures that were previously outsourced, in collaboration with local suppliers and following several years of development.

CO₂ Reduction with Dry-Ice-Free and Consolidated Cargo Transportation

In 2021, together with Yamato Transport Co., Ltd., we developed a consolidated cargo transportation system at an ultra-low temperature of -70°C for reagents for gene testing that was dry-ice-free. Furthermore, in 2022, we achieved completely dry-ice-free transportation of quality control materials for clinical chemistry testing in cooperation with Toho Pharmaceutical Co., Ltd. In 2024, we expanded this initiative to other distributors, delivering to over 200 customer facilities dry-ice-free, thereby contributing to CO2 emission reductions and improved safety.

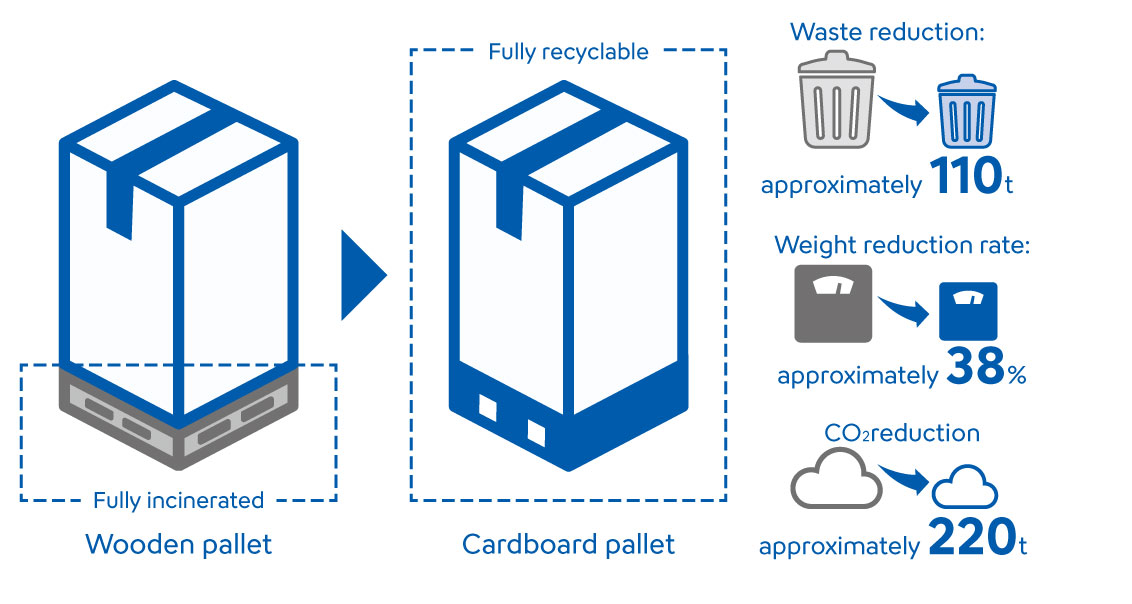

Saving Resources by Reviewing Distribution Packaging

In addition, for overseas transportation of bio-diagnostic reagent, we are reducing waste by promoting the reuse of refrigerants. In transportation from Japan to China, reuse was implemented, and in fiscal 2024, we achieved a reduction of 5.7 tons of waste.

Recycling of containers and packing and utilization of environment compliance materials

Group companies are also advancing environmentally friendly product packaging. At Oxford Gene Technology Inc., the “Green packaging project” was launched, realizing a new product package that reduces plastic usage by approximately 97% compared with previous packaging.

Initiatives at Group Companies: Collaboration with Distribution Partners Considering the Environment

In its selection criteria for distribution partners, Sysmex Europe includes a certified environment management system and the use of green distribution. HITADO, a Sysmex Group company, selects distribution partners who proactively use renewable energy and electric vehicles, while Sysmex Malaysia uses reusable vacuum insulation boxes for product transportation requiring thermal management, reducing CO2 emissions by saving electricity and generating less polystyrene box waste. In addition, Sysmex Turkey stores products in external warehouses with solar panels installed and undertakes other initiatives to reduce environmental impact in collaboration with its partners.

| Company | Initiatives |

|---|---|

| Sysmex Reagents America |

|

| Sysmex Europe Other affiliates in the EMEA region |

|

| Sysmex Malaysia |

|

| Sysmex Australia |

|

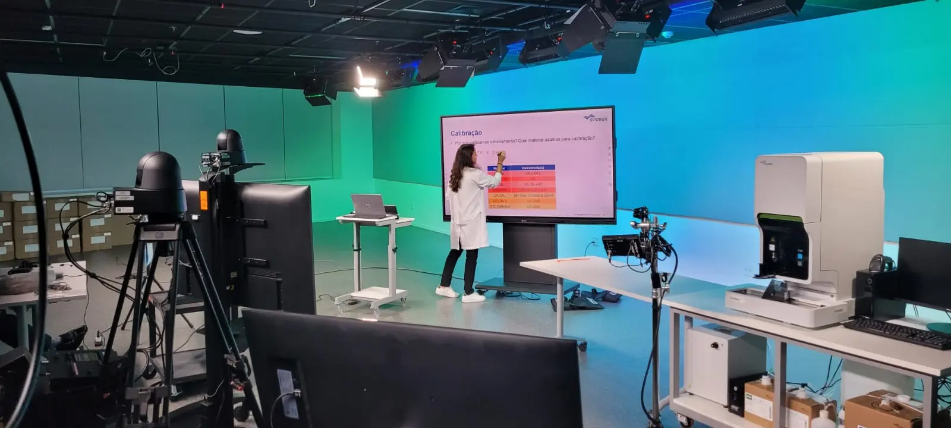

Environmental Consideration in Product Training

Sysmex is working to reduce CO2 emissions associated with participant travel by developing and expanding environments that allow user training on instrument operation and maintenance, as well as scientific seminars, to be conducted online in regions around the world. In addition to e-learning, which enables customers to acquire skills anytime and anywhere at their convenience, we also provide highly immersive virtual training through fully equipped online studios, making it possible to deliver standardized, high-quality product training even in regions far from training centers.

Furthermore, Sysmex offers training programs in virtual environments for the Company’s and distributors’ technical service staff and application support staff to acquire specialized product skills. By increasing the ratio of training provided online, we are promoting both high customer satisfaction and the reduction of CO2 emissions.

Environmental Considerations in the Use and Disposal of Products

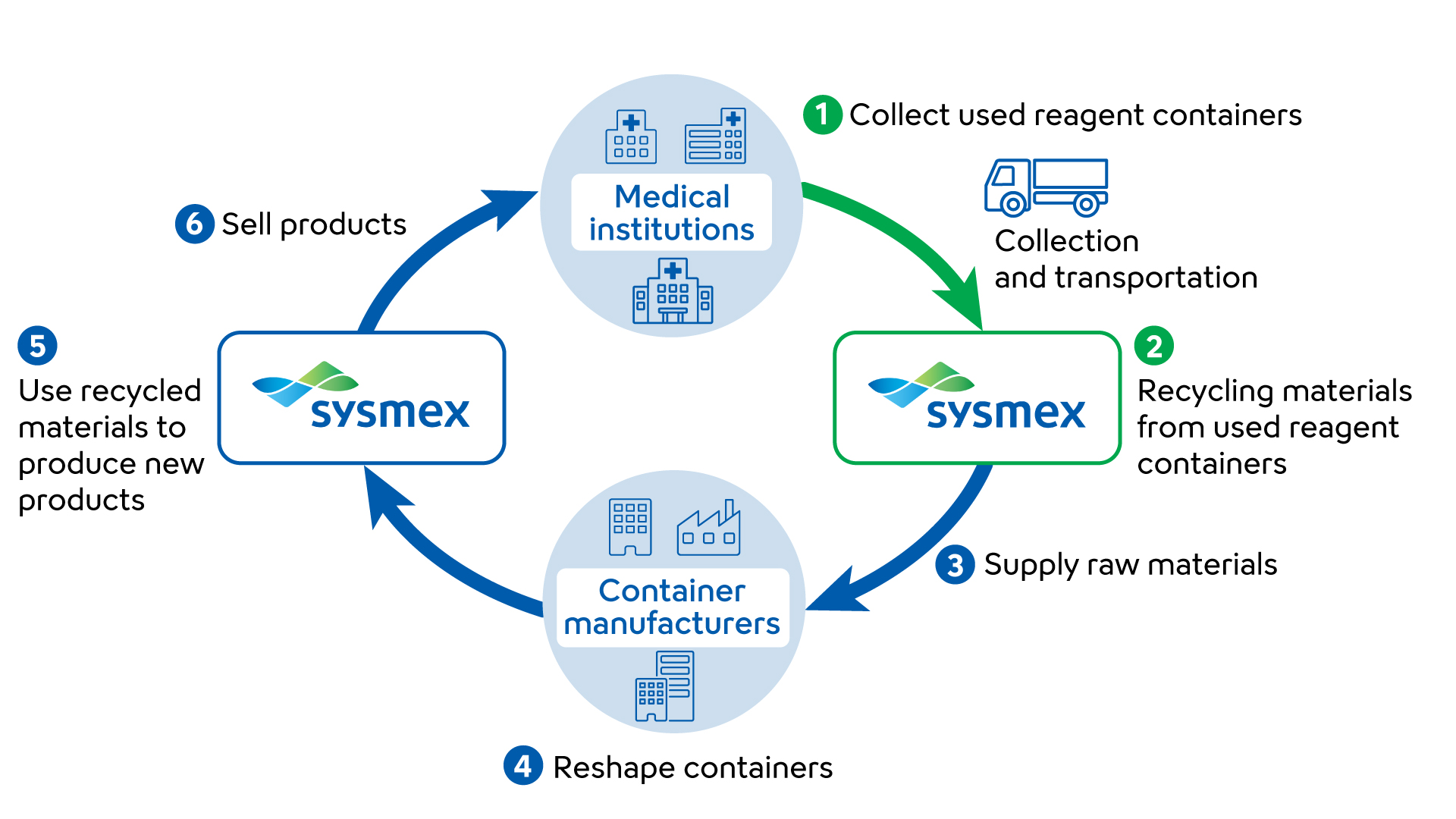

Industry-First to Obtain Certification for Closed-loop Recycling of Reagent Containers under the Plastic Resource Circulation Act

In January 2025, Sysmex became the first in the industry1 to begin closed-loop recycling2 of plastic reagent containers. While this had previously been considered difficult in the healthcare industry due to quality requirements, Sysmex has made this possible by securing recycled resins that meet medical-grade standards, thereby realizing the re-materialization of used plastic reagent containers. This initiative will contribute to reduce virgin resin consumption for container materials (by approximately 30%) and lowers CO2 emissions associated with disposal of used containers (by around 15 tons annually)3.

Furthermore, in June 2025, Sysmex has obtained certification for its business plan for "collection and recycling by manufacturers and retailers" under the Act on Promotion of Resource Circulation for Plastics ("Plastic Resource Circulation Act").

This certification will exempt us from obtaining a license from each local government to collect industrial waste when the company collects used plastic reagent containers from medical institutions nationwide. Thus, our business plan to recycle used plastics (five tons per year) will be accelerated. It will also become possible to expand the range of items that are made by closed-loop recycling, which will contribute to reducing costs. Going forward, we will continue to strive to realize a sustainable, circular resource society.

- 1 Sysmex research

- 2 A recycling method in which used products are re-used as raw materials to manufacture the same type of products again

- 3 This is an estimate by Sysmex, based on the information from the manufacturer, that 500g of CO2 is generated when 160g of a similar plastic container is incinerated, multiplied by the amount of used containers generated by our company.

Saving Resources by Recycling Parts

Since 2023, Sysmex has been selling maintenance parts from analyzers as valuable materials instead of disposing of them. Beginning in 2024, we have also been selling analyzers that were damaged during transportation and could not be marketed as valuable materials. As a result of these efforts, we reduced waste* by 10.3 tons in fiscal 2024.

- Calculated by assuming all waste as plastic and using the industrial waste conversion factor set forth by the Ministry of the Environment

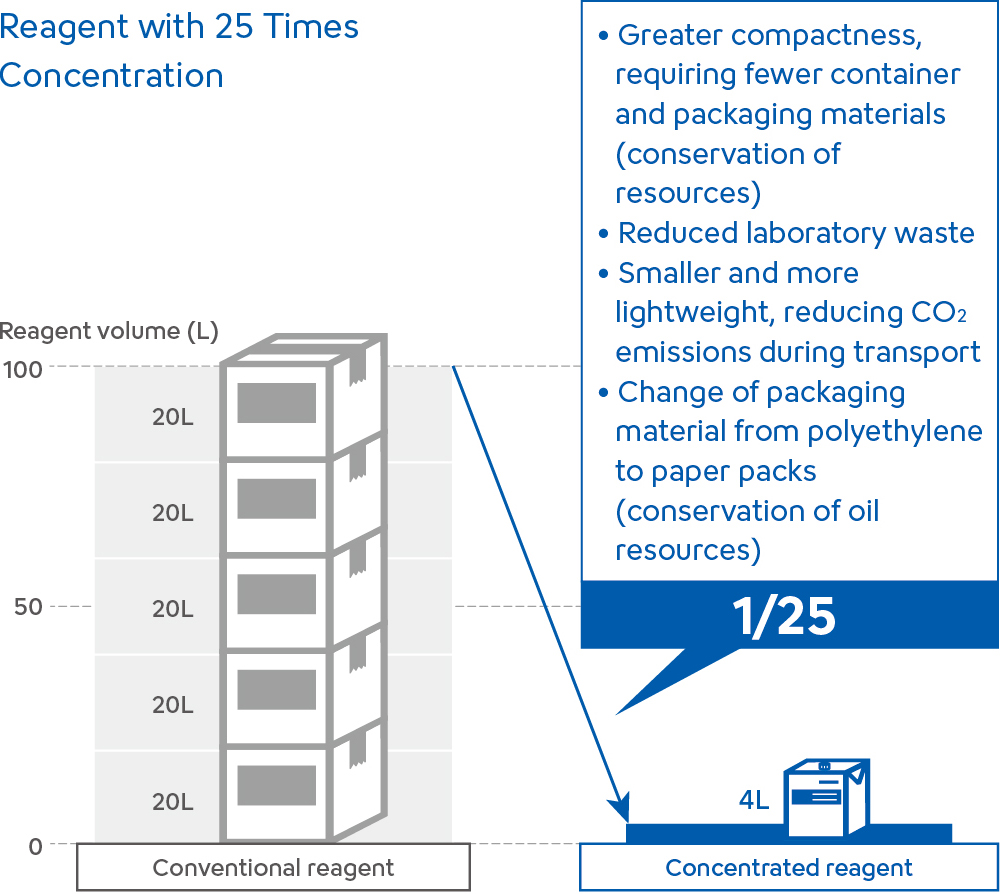

Reducing environmental impact and improving usability through concentrated reagents

For some analysis devices in the hematology field, Sysmex provides reagents that are 25 times more concentrated than traditional ones. Employing these concentrated reagents contributes significantly to improving usability by reducing the frequency of reagent replacement in laboratories and saving warehouse space. Additionally, concentrated reagents enable us to care for the environment by not only reducing the amount of disposed containers and packing materials but also reducing CO2 emissions during transportation. Lastly, we have set a concentrated agent penetration rate as a sustainability target and will work on initiatives to reduce the environmental impact.

Enhancing Safety and Environmental Considerations Through Methanol-Free Staining Solution and Compatible Instruments

Sysmex has initiated a new program to harmonize healthcare workplace safety and environmental sustainability. Evaluations of blood cell morphology in blood testing have been made using methanol-containing staining solutions to prepare blood smear samples. However, medical institutions have encountered significant challenges, including the health risks to medical professionals from methanol toxicity, rising costs associated with regulatory compliance, and environmental burdens posed by hazardous substances.

To resolve these issues, Sysmex has launched a methanol-free staining solution and corresponding instruments,* providing a solution that supports safe and secure laboratory operations. This will reduce the health risks associated with the use of methanol and will also reduce the costs and risks associated with its transportation and storage, thus contributing to improved operational efficiency at medical institutions. Furthermore, reducing harmful substances will lead to reduction of environmental impacts.

We remain committed to integrating solutions that harmonize healthcare safety with environmental responsibility across our products and services, thereby strengthening stakeholder trust and enhancing corporate value.

- The initial release is scheduled for selected regions in Europe and the United States, with subsequent expansion to additional markets.