Environment

Reduction in Environmental Burden through Business Activities

Involvement with Biodiversity

Sysmex considers it essential to address “natural capital,” including water, forests, and soil, alongside climate change countermeasures, and pursues an integrated approach to these challenges. In 2025, based on the recommendations of the TNFD, we identified freshwater and soil as natural capital most relevant to our business activities in terms of dependencies and impacts. Considering our resource usage and production scale, we selected three sites in Japan for an environmental impact assessment. We evaluated the effects on nearby areas and assessed Sysmex's actions and their effectiveness in using resources properly. The assessment found no significant environmental impacts on the surrounding areas. In the future, we plan to gradually increase the number of sites we assess.

| Site | Main dependencies and influences | Impact on the community | |

|---|---|---|---|

| Technopark | Fresh water | Use of groundwater | No adverse effects on the surrounding area, such as land subsidence, have been confirmed due to its use. Establish a continuous monitoring system for proper management of water resources and reduction of water consumption, such as reporting to Kobe City once every two months. |

| Ono factory | Fresh water | Use and discharge of water resources | Compared to the amount of water distributed by the municipality, the impact on the community is limited. The annual usage and emissions tend to decrease. |

| Soil | Use of plastic containers | Compared to the total production of plastic materials in Japan, the amount used is extremely small, and the impact on the environment is limited. Further reduction in consumption is expected through horizontal recycling and substitution of environmentally friendly materials. |

|

| i-Square | Soil | Use and disposal of metals (Iron) | Compared to the total amount of iron produced in Japan, the impact on the environment is limited as a very small amount of iron production. With a recycling rate of 96% and the conversion of waste into valuable materials, we are making effective use of resources at a high level. |

Initiatives to Reduce Greenhouse Gas Emissions

Efforts to Reduce Greenhouse Gas Emissions at Business Sites

Sysmex is working on energy conservation through the introduction of equipment such as highly efficient air conditioning systems, LED lighting, and motion sensors, as well as demand-control systems for measuring and monitoring the amount of electricity needed to reduce direct and indirect greenhouse gas emissions from our business sites.

In fiscal 2023, all electricity used by major domestic facilities, including reagent production factories and R&D centers, was switched to renewable energy sources. Sysmex RA, one of the Group’s key factories, received Net Zero Energy Building (ZEB1) certification under the Building-Housing Energy-efficiency Labeling System (BELS2) for its new facility, which is scheduled to begin operations in April 2025.

Sysmex Europe’s reagent production factory has introduced ice thermal storage air conditioning systems3, in addition to having solar panels installed, covering approximately 35% of energy requirements for reagent production. In addition, Sysmex business locations in EMEA4 and the Americas have been increasing their usage of electricity derived from renewable energy.

Sysmex America has formed a cross-departmental Green Team to promote environmental activities with a view to obtaining LEED certification5 for its head office. It has also installed charging ports for electric vehicles, improved LED lighting, and installed solar panels, continuing to undertake various initiatives to acquire certification.

- 1 ZEB (Net Zero Energy Building): A building that aims to achieve a net zero annual volume of primary energy consumed and generated by installing highly efficient facilities systems to realize significant energy savings (energy conservation) while still maintaining the quality of the indoor environment and introducing renewable energy (energy creation)

- 2 BELS (Building-Housing Energy-efficiency Labeling System): A system to label energy saving efforts of buildings in accordance with the Act on the Improvement of Energy Consumption Performance of Buildings (Buildings Energy Efficiency Act)

- 3 Thermal energy storage technology using ice

- 4 Europe, the Middle East, and Africa

- 5 LEED evaluates the environmental performance of a building from the viewpoints of environmental burden reduction and the health of its users. Evaluation items include the efficiency of water usage, optimization of energy use, conservation of resource materials, and building air quality.

-

New Factory (Sysmex RA) -

Major Initiatives at Each Business Site

| Initiative | Company | Details |

|---|---|---|

| Increase the efficiency of equipment and facilities | Sysmex Corporation |

|

| Sysmex CNA |

|

|

| Sysmex America |

|

|

| Sysmex Europe |

|

|

| Sysmex Asia Pacific |

|

|

| Sysmex India |

|

|

| Jinan Sysmex |

|

|

| Sysmex Wuxi |

|

|

| Introduce renewable energy | Sysmex Corporation |

|

| Sysmex America Sysmex Reagents America |

|

|

| Sysmex Europe |

|

|

| Sysmex UK |

|

|

| Jinan Sysmex |

|

|

| Raise employee awareness | Sysmex Europe |

|

| Sysmex Malaysia |

|

|

| Sysmex India |

|

|

| Sysmex Brazil |

|

- Acronym for “Pollution Under Control,” which certifies that vehicle emissions are below pollution regulation standards.

Decreasing CO₂ Emissions from Company Vehicles

We are also promoting the introduction of environmentally friendly vehicles and fuels across its global operations. Sysmex Brazil uses biofuels derived from sugarcane for its company cars and is expanding the use of electric vehicles for deliveries from its own warehouses to customers. Sysmex UK has eliminated diesel vehicles and replaced all company vehicles with hybrid models.

Using Water Resources Efficiently

Reducing Water Consumption

Sysmex uses water as a raw material in reagent production. Both tap water and groundwater are used. Recognizing that reducing water use is an important issue, Sysmex has set targets for decreasing water use in our Eco-Vision 2033, and it is making efforts to improve the efficiency of water use at reagent production sites.

At the Ono Factory, a reagent production factory, Sysmex has successfully reduced the number of line cleanings by increasing the number of consecutive production runs for the same product, after thoroughly confirming there would be no impact on product quality. In addition, by reviewing production processes, we have developed technology to recover and commercialize the reagents without discarding remaining liquid in the piping. These initiatives have contributed to reducing water use and lowering environmental impact from waste liquid.

Major Initiatives at Each Business Office

| Company | Initiatives |

|---|---|

| Sysmex Corporation |

|

| Sysmex Asia Pacific |

|

| Sysmex India |

|

| Sysmex Brazil |

|

| Sysmex Wuxi |

|

- A system that purifies and reuses wastewater from factories through multiple treatment methods, thereby eliminating wastewater discharge outside the factory premises.

-

New Production Base in India

Wastewater Management and Processing

Major Initiatives at Each Business Office

| Company | Initiative |

|---|---|

| Sysmex Corporation |

|

| Sysmex RA |

|

| Sysmex America |

|

| Sysmex Asia Pacific |

|

| Jinan Sysmex |

|

Managing and Recycling Waste

Reducing Waste and Promoting a Stable Recycling Rate

Sysmex carries out initiatives to reduce waste and increase recycling rates. At our research and development base, Technopark, we introduced polystyrene foam melting machines and large shredders for confidential paper in fiscal 2023. With this equipment, we can convert all used polystyrene foam generated from the office into recycled plastic materials and sell them as valuable resources. We also process the shredded wastepaper from large shredders to be reused as toilet paper. By doing this, we can significantly reduce the volume of waste.

In addition, we began selling as valuable resources our own and metal scrap from unneeded freezers and refrigerators, resulting in approximately 56 tons of recycled resources in fiscal 2024.

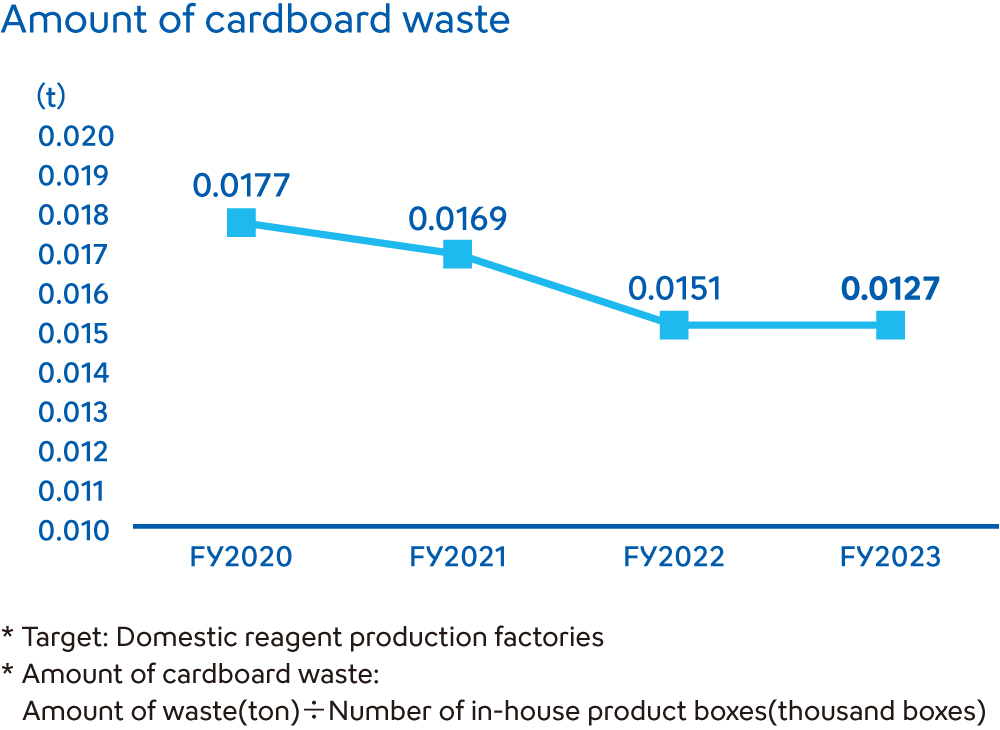

In its domestic reagent production factories, Sysmex promotes environmental initiatives in collaboration with its business partners and has successfully reduced the waste of packing materials for delivery by reusing cardboard, reviewing excessive packaging, and changing the practice of over-packaging.

At our domestic instrument production factories, i-Square and Kakogawa Factory, we conducted trial separation of mixed plastic waste and sold approximately 10 tons as valuable resources in fiscal 2024. Furthermore, at Kakogawa Factory, food waste from its in-house canteen is reduced using a specialized garbage disposal system that converts food waste into organic fertilizer for farmers. The factory purchases agricultural produce grown by the farmers who use this fertilizer, contributing to the realization of a circular economy.

Promoting Digital Data

Sysmex works to reduce its use of paper by utilizing personal computers, tablets, and smartphones to send and receive data. These efforts have reduced paper use and waste. Our manufacturing facilities are also working to switch to electronic production records and manuals, promoting our paperless initiative.

Major Initiatives at Each Business Office

| Company | Initiative |

|---|---|

| Sysmex America |

|

| Sysmex Brasil |

|

| Sysmex Medica |

|

| Sysmex Asia Pacific |

|

| Sysmex Malaysia |

|

| Sysmex Jinan |

|