Stories

Undertaking the Never-Ending Mission of “Creating a Stable Supply of Reagents”

- Efforts by Sysmex to Maintain Laboratory Testing During the COVID-19 Pandemic -

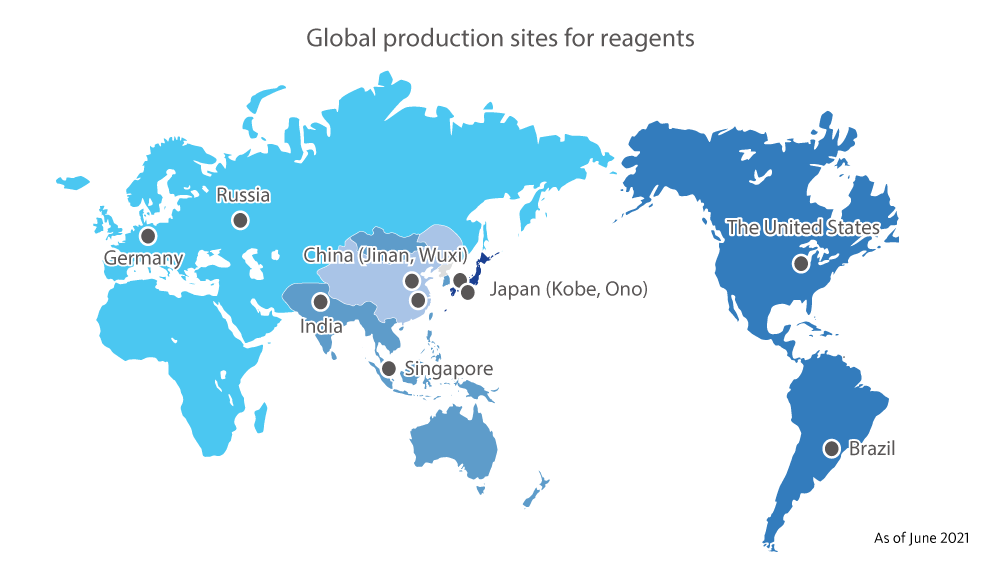

In vitro diagnostics (IVD) using blood or urine samples play an important role in the diagnosis and treatment of diseases, and reagents are an essential component of such laboratory tests. In order to ensure the stable supply of these reagents, Sysmex not only maintains close coordination within the Group, but also works closely with raw material manufacturers and other business partners to build a robust global supply network. Through these day-to-day activities, the Group has maintained a stable supply even in the face of drastic changes in the circumstances surrounding our entire supply chain, including procurement and production during the COVID-19 crisis. Below is a look at its efforts to contribute to clinical environment of healthcare professionals and the healthy lives of people while overcoming many different obstacles.

Pandemics Cause a Huge Impact on the Stability of Supplies

A Firm Determination to Guarantee Delivery even Under Difficult Circumstances

“Because reagents from Sysmex are one of the products needed right now in the pandemic, we must never stop supplying them. It is this passion that has driven everyone involved to work together as one team. We have taken many measures, and we have managed to keep supplying our products stably thanks to our internal and external networks including our business partners, which we have steadily built up to create a robust supply system. As a person involved in procurement, I am proud that the activities we have consistently pursued are helping us to get through this emergency situation.” Yamagata's confident words are filled with a sense of responsibility as a member of the team supporting Sysmex’s supply chain.

Connecting the Flow of Manufacturing with Trust

Surviving Through a Period of Turmoil and Uncertainty

Looking back on the pandemic months that made Yamagata more keenly aware than ever of our never-ending mission of stably supplying reagents, he says the challenge has provided him with many new insights.

Related Information

Related Keywords

- Information contained in the stories is current as of the date of the announcement,

but may be subject to change without prior notice.